|

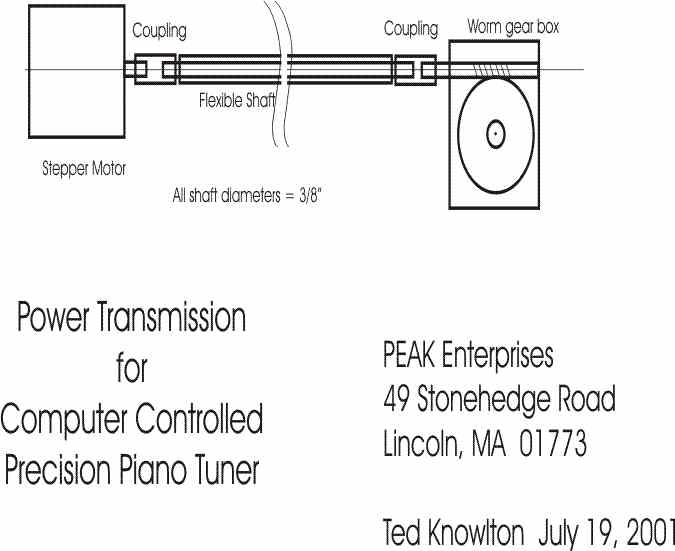

Stepper motor on right

connects through a flexible shaft to a worm gear box.

The gear box output shaft connect directly to a tuning pin on the piano. |

|

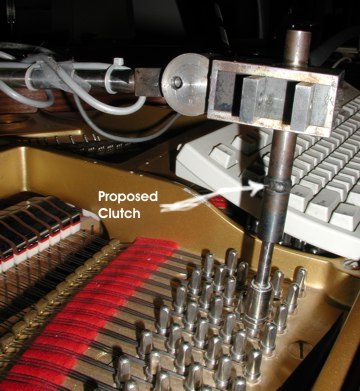

Another view of the worm gear box. |

|

A close-up of the worm gear box showing the connection with the torque restraining bar. |

|

The torque restraining

bar clamps to the frame of the piano. The white wire is a connection

to a strain gauge mounted in the middle of the bar. The strain gauge

indicates to the PC control program the amount of strain in the torque

restraining bar.

The U-joint allows the whole mechanism to be moved to any tuning pin on the piano. |